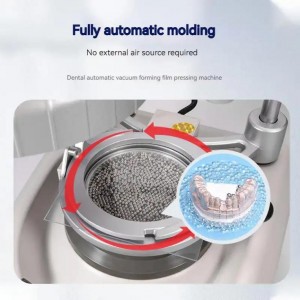

Kev Ntsuas Nias Tshuab Qhov Ntse Ntse Tag Nrho-Tsis Siv Neeg Nqus Plav Ua Kev Siv Hniav Tshuab Khaub Ncaws Orthodontic Retainer Zaj Duab Xis

Kev Ntsuas Nias Tshuab Qhov Ntse Ntse Tag Nrho-Tsis Siv Neeg Nqus Plav Ua Kev Siv Hniav Tshuab Khaub Ncaws Orthodontic Retainer Zaj Duab Xis

| Khoom npe | Tag Nrho Cov Nqus Plua Plav Kev Siv Lub Tshuab |

| xim | nyiaj |

| Kev Ua Haujlwm Zog | 350W |

| fai fab hov ntau | 220V / 50Hz ± 10%, 110V / 60HZ + 10% |

| ntsuas | 335 * 325 * 403 hli |

| qho hnyav | 12Kg |